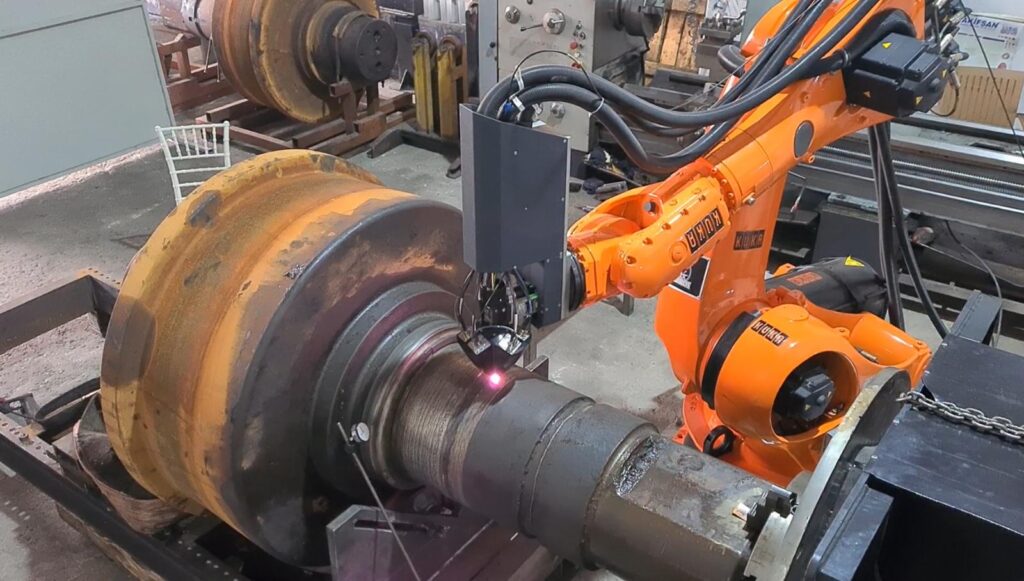

Mainly the laser beam creates a molten mixture pool of the added material (mainly powder, wire or a mixture of wire and powder) on the base metal without pores and cracks under the dedicated spot. The main principle is to create an overlay surface on the substrate surface. High strength metallurgical bond after cladding improves the properties of the base metal in most cases. (Which is the one of the main idea for laser cladding) As a result. the idea is adding one material on another under a controlled coating process. The material property changes caused by the heat input are minimal.

With the superiour features of laser cladding compared to conventional welding methods such as MIG, TIG and others, laser cladding is becoming the first choice for the industry. Very limited applications are outside the scope of laser cladding. With the latest improvements of the laser characteristics this rare deficincy will be over.

Fabros Technology is becoming the key solution address for Laser Cladding needs in Turkey and the neigbour countries.

BENEFITS

- Minimal cracks

- Low heat input

- Minimal porosity

- Low heat affected zone

- High surface quality

- Minimal distortion

- Near net-shape deposit, very low post-processing

- Minimal heat treatments needs

- Short laser cladding process compared to conventional methods

- High energy efficiency

- Minimal distortion

- Ideal for both new and used components

- Wide range of coating materials

- Cost-effective

- Strong metallurgical bond

- Minimal base material dilution into the coating

- Customized precise coating thickness

- Surface modification

- Lower part weights and costs

- Higher life time of the equipments

INDUSTRIES SERVED

- Steel Industry

- Pulp & Paper Industry

- Mining Industry

- Recycling Indutsry

- Marine Industry

- Energy Industry

- Agriculture Industry

- Transport Industry

- Glass and Insulation Industry

- Cement Industry

- Wood processing Industry

- Refractory Processing

- Fibre Glass production

- Pulp & paper production

- Wood Processing

- Mineral processing

- Cement Production

- Oil & Gas Industry